Researchers at Keio University and the National Institute of Advanced Science and Technology have developed an AI and infrared-based method to reveal internal defects in carbon-fiber composites, with broad applications in aerospace, automotive, and infrastructure industries.

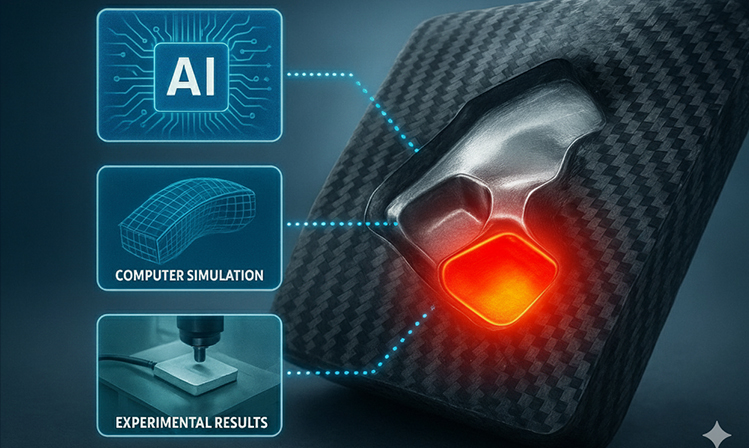

A visualization of the framework for predicting the three-dimensional structure of internal defects in carbon-fiber-reinforced plastics (CFRP). The image was generated with ChatGPT.

Carbon-fiber-reinforced plastics (CFRP) are prized for their strength, light weight, and durability. These qualities have made them indispensable in industries such as aerospace and automotive manufacturing, where reducing weight without sacrificing safety translates directly into improved performance and lower fuel consumption. Yet CFRP is not without challenges: during production and use, internal defects such as delamination, fiber fractures, or foreign object inclusions can occur, compromising reliability. Detecting these flaws quickly, safely, and cost-effectively has remained a pressing issue.

A research team led by Mayu Muramatsu Keio University has developed a breakthrough solution by combining infrared imaging with AI. Their study, recently published in Composites Part B, introduces a new nondestructive testing method that promises to make defect detection in CFRP both faster and cheaper.

From Heat to Hidden Defects

Traditional inspection methods for CFRP―such as ultrasonic scanning or X-ray imaging―are reliable but costly, time-intensive, and often require strict safety protocols. Infrared stress measurement is a simpler and safer alternative for evaluating materials. It works by detecting the minute temperature changes that occur when a load is applied and, using thermoelastic theory, translates those changes into stress variations. However, interpreting the yielded infrared imaging to accurately reconstruct internal defects has long been a hurdle.

The Keio-led team tackled this challenge by applying machine learning. They used convolutional neural networks (CNNs), a form of AI adept at pattern recognition, trained with data from both computer simulations (finite element analysis) and real infrared stress measurements. This dual approach allowed the system to "learn" from large, simulated datasets while fine-tuning its accuracy with smaller, experimentally gathered ones―a process known as transfer learning.

Predicting the Invisible in Three Dimensions

The resulting framework is able to predict the three-dimensional structure of internal CFRP defects using only surface-level infrared stress data. Remarkably, the AI could distinguish whether a sample contained a defect, identify its approximate location, and even reconstruct its depth within the layered composite. The researchers confirmed that their method maintained high accuracy even when noise from experimental conditions was introduced.

One key advantage is speed. Once trained, the AI model can analyze a new sample in under a second. This efficiency represents a dramatic improvement over conventional methods, which may require hours of scanning or simulation. As the number of inspections increases―for instance, in mass-production environments―the benefits of AI-driven analysis become even more significant.

Toward Lighter, Longer-Lasting Infrastructure

If widely adopted, this technology could reduce both the manufacturing and maintenance costs of CFRP-based structures. For industries like aerospace and automotives, this translates into safer, lighter, and more affordable vehicles. Beyond transportation, CFRP is also used in infrastructure projects, such as bridges and wind turbine blades. Extending the lifespan of these structures by detecting flaws before they lead to failure could have profound economic and societal impact.

Kojima posits that the team's method demonstrates how AI and physics-based modeling can complement each other to solve long-standing industrial problems. By transforming nondestructive testing into a faster, safer, and more affordable process, this research opens new doors for sustainable materials engineering.

Published online 11 November 2025

About the researcher

Yuta Kojima ― Graduate Student

Graduate School of Science and Technology

Ph.D. (Engineering), Graduate School of Science and Technology, Keio University, 2025. He is currently an Assistant Professor at the Graduate School of Engineering, Nagoya University. His research focuses on non-destructive testing of CFRP structures.

Mayu Muramatsu ― Associate Professor

Faculty of Science and Technology

Ph.D. (Engineering), Graduate School of Science and Technology, Keio University, 2012. After serving as a Researcher at the National Institute of Advanced Industrial Science and Technology (AIST) and as an Assistant Professor at Tohoku University, she is currently an Associate Professor in the Department of Mechanical Engineering, Faculty of Science and Technology, Keio University. Her research focuses on solid mechanics.

Links

Reference

- Kojima, Y. et al. Transfer-learning-aided defect prediction in simply shaped CFRP specimens based on stress distribution obtained from finite element analysis and infrared stress measurement. Composites, Part B, Eng 291, 111958 (2025). | article